Diagnosing Common Turbocharger Issues in Diesel Engines

Professional diesel repair specialists utilize systematic diagnostic approaches to identify and address turbocharger issues before significant failures occur through comprehensive testing procedures.

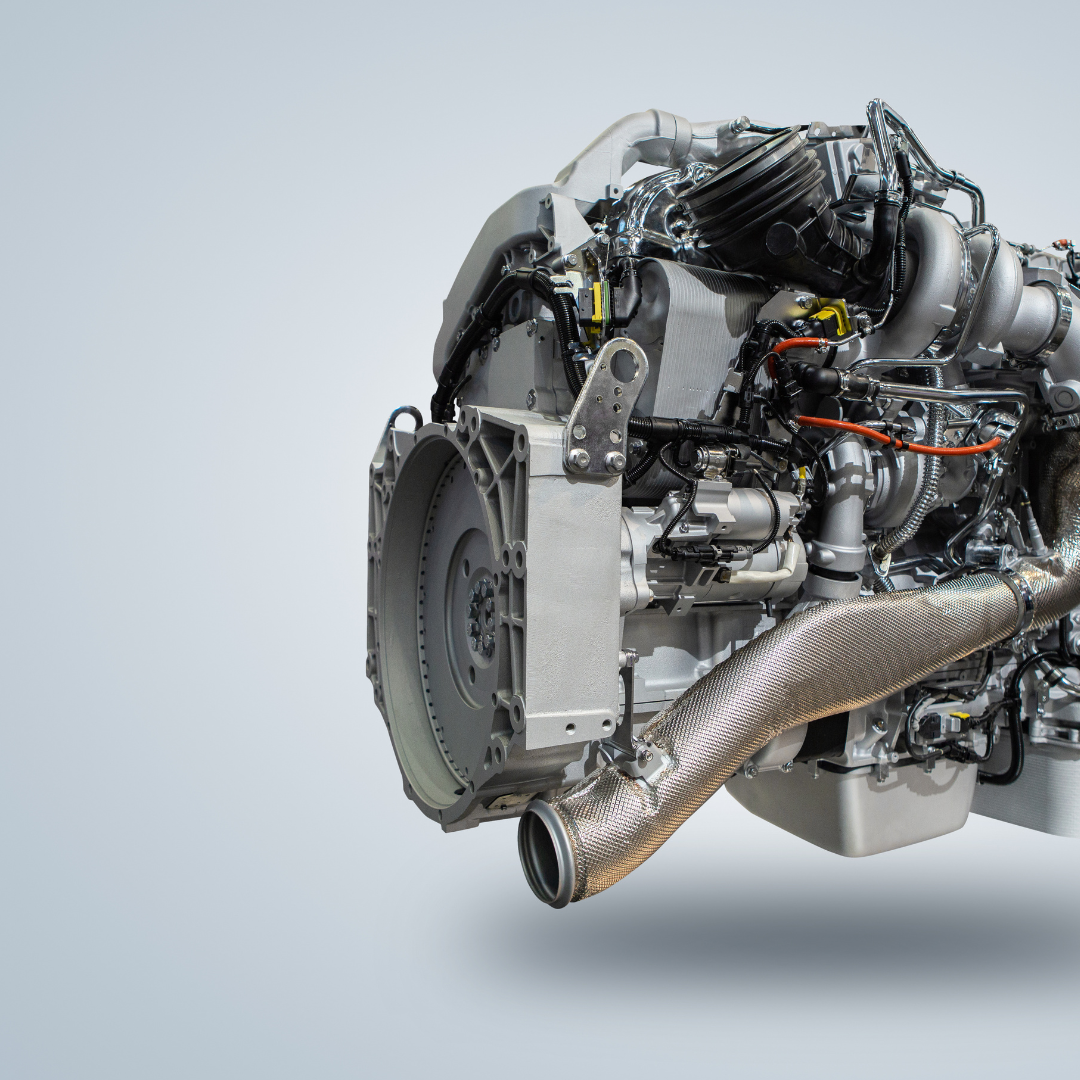

Turbocharger problems in diesel engines can significantly impact performance and efficiency levels. Professional diesel repair specialists utilize systematic diagnostic approaches to identify and address turbocharger issues before significant failures occur through comprehensive testing procedures.

Common Warning Signs

Various symptoms indicate potential turbocharger problems in modern diesel engine systems. Diesel repair technicians look for unusual noises, excessive exhaust smoke, and power loss. Early detection prevents catastrophic failures and reduces repair costs while maintaining optimal performance.

Loss of Power

Reduced engine power often signals turbocharger issues in diesel-powered vehicles today. Diesel repair experts evaluate power loss patterns to determine specific causes immediately. Proper diagnosis differentiates between turbocharger and other engine problems through systematic evaluation.

Excessive Smoke

Different colored exhaust smoke indicates specific issues in turbocharger system operation. Diesel repair professionals interpret smoke characteristics to identify turbocharger problems accurately. Smoke analysis helps pinpoint exact failure points through detailed visual examination.

Unusual Noises

Distinctive sounds often accompany turbocharger problems in both new and old engines. Diesel repair specialists recognize various noise patterns immediately, indicating specific issues. Proper noise diagnosis guides repair approaches effectively through professional acoustic analysis.

Oil Consumption

Increased oil consumption may indicate turbocharger seal failures requiring immediate attention. Diesel repair technicians check oil levels and conditions regularly for contamination. Oil analysis reveals early warning signs of turbocharger wear through laboratory testing.

Boost Pressure Issues

Irregular boost pressure affects engine performance significantly in turbocharged diesel applications. Diesel repair experts measure and analyze boost pressure variations with precision tools. Proper pressure testing identifies specific turbocharger problems through comprehensive diagnostic procedures.

Component Inspection

Visual inspection reveals many turbocharger problems through careful, systematic examination practices. Diesel repair professionals thoroughly examine components for wear and damage. Regular inspections prevent unexpected failures by early detection of potential issues.

Air Filter Condition

Contaminated air filters affect turbocharger performance and can cause premature wear. Diesel repair specialists emphasize proper filter maintenance schedules for optimal operation. Clean air systems protect turbocharger components effectively through regular maintenance.

Oil Supply Problems

Proper oil flow remains crucial for turbocharger operation in all conditions. Diesel repair technicians verify oil supply system integrity through pressure testing. Regular oil system maintenance prevents turbocharger damage through proactive care.

Wastegate Function

Wastegate problems significantly affect boost control in modern turbocharger systems. Diesel repair experts test wastegate operation thoroughly using specialized diagnostic equipment. Proper wastegate function prevents over-boost conditions through precise calibration procedures.

Electronic Controls

Modern turbochargers utilize complex electronic controls requiring specialized diagnostic equipment. Diesel repair professionals diagnose electronic system issues accurately using advanced tools. Proper electronic diagnosis guides repair decisions through comprehensive system analysis.

Temperature Management

Excessive temperatures damage turbocharger components and reduce overall system efficiency. Diesel repair specialists monitor temperature patterns carefully using thermal imaging equipment. Proper cooling system maintenance protects turbocharger longevity through temperature control.

Intake System Integrity

Air leaks affect turbocharger performance significantly and can cause system failures. Diesel repair technicians check intake systems thoroughly using pressure testing equipment. Proper sealing maintains turbocharger efficiency through regular system inspection protocols.

Exhaust System Condition

Restricted exhaust flow impacts turbocharger operation and overall engine performance levels. Diesel repair experts evaluate exhaust system conditions regularly using flow testing. Proper exhaust maintenance prevents turbocharger stress through systematic inspection procedures.

Maintenance History

Previous maintenance affects turbocharger reliability and influences current system performance levels. Diesel repair professionals review maintenance records carefully to identify potential issues. Proper maintenance documentation guides diagnostic processes through historical data analysis.

Operating Conditions

Specific operating conditions influence turbocharger wear patterns over extended service periods. Diesel repair specialists consider operating environments when diagnosing issues thoroughly. Environmental factors affect maintenance requirements significantly through various operational stresses.

Testing Procedures

Systematic testing identifies specific problems accurately through comprehensive diagnostic protocols. Diesel repair technicians follow comprehensive diagnostic procedures using advanced testing equipment. Proper testing prevents misdiagnosis and unnecessary repairs through careful analysis.

Preventive Measures

Regular maintenance prevents many turbocharger problems through systematic preventive care. Diesel repair experts recommend specific maintenance schedules based on usage patterns. Preventive care extends turbocharger service life significantly through regular professional maintenance.

Understanding turbocharger operation and potential problems helps effectively maintain diesel engine performance and reliability. Professional diesel repair services provide essential expertise in promptly diagnosing and addressing turbocharger issues. Regular maintenance by qualified technicians prevents many common problems while substantially extending component life. Working with experienced diesel repair specialists helps identify developing issues before major failures occur consistently. Proper diagnosis and maintenance protect valuable engine components while maintaining optimal performance levels continuously.

KTS Enterprise in Phoenix offers comprehensive mobile fleet truck repairs catering to client needs, from preventative service to major repairs. We offer mobile and in-shop repair, lube and oil changes, annual dot and bit inspections, check engine and dash lights, suspension repairs, drivetrain repairs, and tire solutions.